The typical Industrial Internet of Things (IIoT) landscape depends on multiple hardware and software components working in tandem to deliver insights. What’s an “insight”? That’s the perfect question and the biggest problem. Insights should be defined as revelations found through analysis that transform how we think, how we act, and what we do next. But, in reality, “insights” is a buzzword used by many to describe a graphics package that colorfully displays your data through someone else’s eyes.

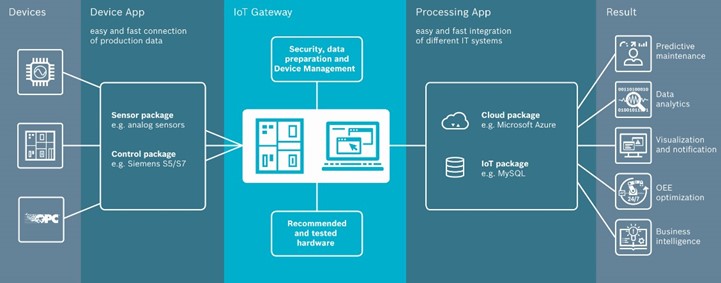

In your spare time, Google “IoT Flow”. More often, sensors are installed on machines and connected to a gateway that collects the raw data. Raw data is then sent to a cloud-gateway to be aggregated using control applications. If machine learning is a component of your IoT landscape, these applications are influenced by a “model” – a unique set of algorithms designed to transform raw data into metrics – and sent back to the cloud-gateway. No insights yet, just scrubbed or cleansed data.

Next, your raw data and cleansed data are sent from the gateway to a data processing application and then a data warehouse where it is stored until called upon by an information system, a report generator or graphics package, another sensor, or Bluetooth connected mobile application. Still no insights, just stored data.

Within our Asset Management community, most IoT landscapes pull data from the data warehouse into a graphics package where additional data transformations occur using predefined calculations, like FFT, MTBF, OEE, or Cost per Unit. The transformed data is graphically depicted in bar charts, pie charts, and sometimes 3D illustrations to create an assumption that the IoT network of components has solved the unsolvable. NOPE! Still not insights, just a graphical representation of your data.

It’s funny. When I’ve discussed this topic with IoT experts the most common response I get is, “My dude…just take out ‘big data’ and replace it with block chain. Problem solved”. What?@! Or comments like, “I concur. The core issue is streamlining data transformations to the application.” Nope. Missed it again, “my dude”.

So, all my ranting is meant to say this. If the raw, scrubbed, or transformed data doesn’t automate our decision-making processes for Predictive Maintenance, Asset Location Tracking, or Warehouse Management, then it’s not insightful. It’s still just data.

IoT for Asset Management Needs Action

A good friend and mentor once said to me, “Darrin, if you’re going to identify the problems you better be able to deliver the solutions.” So here I go…

How do we simplify IoT for Asset Management? In short, we understand the physical characteristics of asset-related failures. We define failure modes and quantify the physical effects. We define the causes of each failure mode and the associated human, process, and environmental parameters. With an understanding of Things, we then connect machines, information management systems, our business processes, and our people.

Data Models

You’ve heard me say it a million times, that “a pump is a pump”. Configure your CMMS/EAM software with the failure modes detectable within the pump and the causes that have influence on the pump’s performance. Define the data you need to collect to measure the pump and how to transform this raw pump data into a metric. Then outline the events that will be triggered from the pump’s metrics to automate your process and inform the User.

Data Sources

Using the Data Model as a guide, connect quality data sources with modern asset management software applications that understand how to transform the data you need into the real-time actions you want. If your CMMS/EAM provider tells you that your assets are too old for IoT, then throw them out. They suck!

Failure mode and cause data can be sourced from your machine’s Programmable Logic Controller (PLC), or sensors installed on your machine. Data can be sourced from completed work orders via failure codes, scanned paper documents, or collected via mobile application within the Preventive Maintenance (PM) routine itself. We can even get data from cameras and audio recording devices (just like Alexa). If we know what we need to collect (e.g., the Data Model) then finding a quality data source is the easy part.

As Asset Management Professionals we know how important failure modes are to every risk-based decision-making process. So why don’t we expect failure-based decision-making from our IoT landscape? Stop allowing yourselves to be fooled by graphics, charts, and the lure of mobile applications. THEY’RE NOT INSIGHTS! Focus instead on transforming that vibration or temperature data into an action. Raise a CM work order. Adjust the PM frequency. Reorder that Critical Spare. Do something with the data, in whatever form you can get it. Data “transformation” is not converting Peak-RMS to in/sec. It’s what we do when Peak-RMS reaches 5.6 or 10.1. Streamline the IoT landscape to get to the action, the “DO”, quicker (full stop).